All Polytron Products are 100% solid-free. NONE: Teflon, graphite, molybdenum, ceramics, nano-particles..e.t.c

What makes Polytron Products so unique? Technically speaking in order to understand the way the Polytron Metal Treatment Concentrate (MTC) works, we must first understand a little about the metal that is being treated.

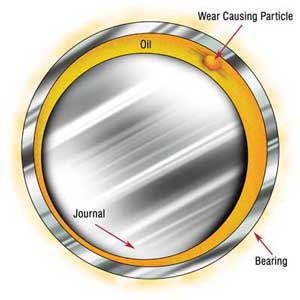

Conventional lubricants are based on maintaining high strength and thickness of oil film, or on introducing an EP (Extreme Pressure) protective deposit between moving mating surfaces to resist failure resulting in scoring, seizure or accelerated wear. When observing mating friction surfaces under high magnification one can see that they are actually full of “mountains” and “valleys.”

These “mountains” penetrate the oil-film that separates the mating friction surfaces, and collide with each other. These collisions, in the micro level, translate into “friction” between the mating friction surfaces in the macro-level. Some of these collisions result in metal particles breaking away from the colliding “mountains.” The breaking away metal particles in the micro-level translate into “wear” process in the macro-level.

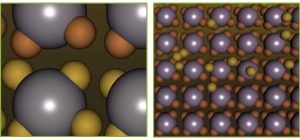

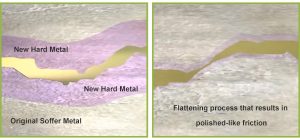

When Polytron is applied, under heat and pressure, some elements of it impregnate, metallurgically, the crystal structure of the metal itself at its mating friction surface. As a result of the metallurgical process, a very thin layer of original metal is converted into a new type of metal that is much harder and has at least 100 times longer wear-life. This newly formed layer of metal protects the original “softer” metal beneath it from any wear. Since the protective layer is very thin, it is very flexible (like a very thin sheet metal).

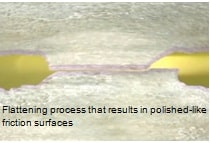

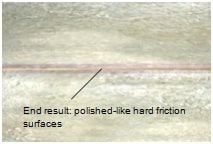

Although during collisions the protective layer does not allow metal particles to break away, its being flexible allows the metal underneath to be pushed horizontally by the horizontal force generated by collisions. Thus the metal on the “mountains” is “pushed” into the “valleys” flattening out the friction surface resulting in smooth polished-like surface that has much lower friction coefficient.

This advanced technology, that allows formation of hard, smooth polished-like surfaces from the original friction surfaces, is one of the main features that makes Polytron MTC so different from other lubricants on the market today.

This feature together with other qualities of Polytron Metal Treatment Concentrate (MTC) additive package contributes to 4 to 7 times longer oil change intervals and 4 to 7 times longer service life of engines and equipment.

When added to grease, motor and transmission oils, Polytron additive packages dramatically reduce wear of the mating friction surfaces in car engines, transmissions, and other equipment (up to 95%), considerably extending their life span. The lower friction results in lower fuel consumption. In the event of lubricant loss, the protective layer provides a temporary protection against failure. More discussions…

There are two main reasons for deterioration in engine performance:

- Continuous wear

- Deposit build-up around piston rings and other moving engine parts.

These two reasons are closely related. Deposit build-up, beyond certain levels, causes accelerated wear of the engine. In turn, this causes deterioration of engine performance, which causes even faster acceleration in deposit build-up….and so on. That is why it is so important to eliminate wear and deposit build-up at the same time.

Polytron is scientifically designed to take care of these major problems even in the harshest working conditions. It is an excellent dispersant which holds sludge harmlessly in suspension while preventing the deposition of varnish and lacquer on engine parts in severe service. Oil filter life is improved and the PVC (Positive Crankcase Ventilation) valve remains free and clean. As long as Polytron is applied properly, engine parts (or parts of any other equipment) remain clean and free of any deposits build-up.

In older cars, Polytron MTC cleans the inner engine and keeps it clean as long as the product is used as recommended. Polytron eliminates up to 99% of engine (or any other equipment) wear. Because of the extraordinary qualities of Polytron referenced above, the performance of an engine (which is not related to fuel system and upper engine) is maintained at its maximum for as long as Polytron MTC is used as recommended.

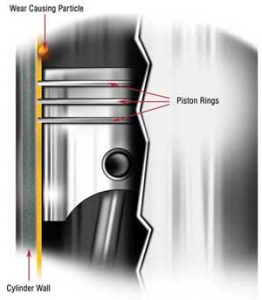

In older car engines, once wear reaches a certain point, there become excessive clearances between the cylinder wall surfaces and the piston rings surfaces (as a result of their “roughness”) which cause partial loss of compression, excessive penetration of oil into the fuel system, and penetration of combustion gases into the oil system. All of the above leads to a vicious cycle of performance deterioration and excessive wear. Using Polytron, the cylinder walls and the piston rings surfaces are “polished” so the clearances between the cylinder walls surfaces and the piston surfaces are minimized and the compression and performance are maximized (in most of the cases the compression is restored completely).

Safety – Polytron provides temporary engine protection during loss of lubrication. Imagine that your engine loses oil or coolant (or oil and/or coolant system pump breaks down) in the middle of nowhere, at night? How much would you pay to be able to drive to the nearest repair shop or a place where you can stay safely overnight?

Polytron offers this feature. After driving your car approximately 25 minutes with our product and using it as recommended later on, you can be assured that in the event of oil/ coolant systems failure, you’ll still be able to drive your car and be assured that you will not ruin your engine or compromise your safety.

In new engines, the use of Polytron keeps the inner engine clean at all times and eliminates up to 99% of its wear. In real terms, the performance of the engine is improved and maintained at its best as long the product is used as recommended.

Immediately after applying Polytron the first time in old engines, the inner engine is cleaned of all deposits. The compression and performance of the engine is maximized. Fuel and oil consumption is minimized. Wear is almost completely eliminated. The engine operates quieter and engine-operating temperature decreases. The same maximum level of performance can be maintained for as long as Polytron is used as recommended.

Polytron provides temporary engine protection during loss of lubrication.

OTHER APPLICATIONS OF POLYTRON METAL TREATMENT MTC

Maximum performance and elimination of wear can be achieved in transmissions, power steering systems, and any other moving subassemblies where appropriate lubricating fluids are used. (10 -15% POLYTRON METAL TREATMENT MTC has to be added.)

Polytron Gasoline /Diesel Conditioner – adds an extra boost to the performance of a car/truck engine. It cleans deposits and gum from the fuel injection system, carburetor, upper engine, valves, and lifters. It keeps the parts of these systems clean for as long as Polytron is applied as recommended. It lubricates and eliminates wear of the moving parts of the upper engine, fuel injection system, valves, lifters and carburetors. It contributes to much cleaner emission gasses (you will not have any problem passing a smog test). The catalytic converter lasts much longer Close